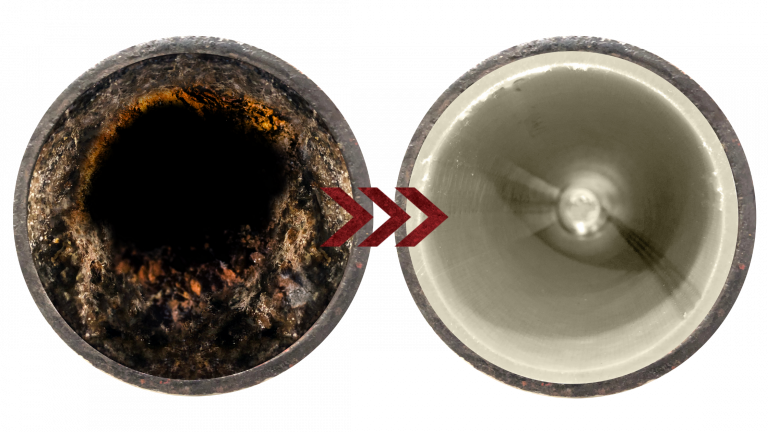

THE NEXT GENERATION OF LATERAL REHAB

The Bluelight LED CIPP lining system for laterals and small drain pipes is the most advanced light-curing system available. The innovative technology empowers CIPP lining pros by alleviating the time pressures of other CIPP systems. The specially formulated resin only cures under light in the “blue” wavelength, giving installers significantly longer working time between liner wet-out and curing. Once installed, the automated curing system pulls the LED light head through the liner, curing the resin almost instantly – up to five times faster than conventional methods. Instead of waiting hours for the liner to cure, a 50’ sewer line could be fully cured in under 10 minutes.

With more than 2 million feet installed worldwide, the Bluelight LED lining system is a proven solution for lateral rehab.

THE NEXT GENERATION OF LATERAL REHAB

The Bluelight LED CIPP lining system for laterals and small drain pipes is the most advanced light-curing system available. The innovative technology empowers CIPP lining pros by alleviating the time pressures of other CIPP systems. The specially formulated resin only cures under light in the “blue” wavelength, giving installers significantly longer working time between liner wet-out and curing. Once installed, the automated curing system pulls the LED light head through the liner, curing the resin almost instantly – as fast as 5.4 feet per minute. Instead of waiting hours for the liner to cure, a 50’ sewer line could be fully cured in under 10 minutes.

With more than 2 million feet installed worldwide, the Bluelight LED lining system is a proven solution for lateral rehab.

BLUELIGHT LED CIPP LINING SYSTEM

EXCLUSIVELY FROM HAMMERHEAD TRENCHLESS

- Cure as fast as 5.1′ per minute (306 feet per hour)!*

- * Curing speeds will vary based on diameter and wall thickness

- Up to 328 ft.

- Navigate 45- and 90-degree bends

- Meets or exceeds ASTM F1216

- Single diameter transition liners available

- Environmentally safe – no styrenes, odors or VOCs1

- Cure as fast as 5.1′ per minute (306 feet per hour)!*

- * Curing speeds will vary based on diameter and wall thickness

- Maximum distance of 164 ft.

- Navigate 45- and 90-degree bends

- Meets or exceeds ASTM F1216

- Single diameter transition liners available

- Environmentally safe – no styrenes, odors or VOCs

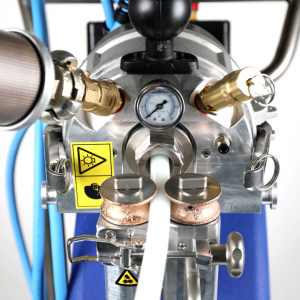

NEW TOUCH SCREEN INTERFACE

The redesigned Bluelight system features an intuitive touch-screen interface that is easy to learn and operate. Simply input the job specs and the system will automatically set pull-back speed. On the screen, the installer can watch curing progress on a live feed from the LED light head’s integrated camera, and the boldly colored gauges make it simple to monitor the system’s performance throughout lining operations.

EXTENDED WORKING TIME

Install liners at your own pace. The Bluelight system resin only cures when exposed to light in the “blue” wavelength (444-457 nm) which gives installers significantly extended working time, alleviating the time pressures of traditional curing methods. The single-part resin does not require any mixing and liner can be wet out in advance of a project if properly stored.

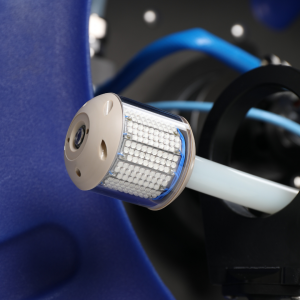

BLUELIGHT LED SYSTEM FEATURES

EXPANDED RANGE

Rehabilitate pipes 3” to 10” in diameter with the system’s 3 light head options

INTERCHANGEABLE REELS

Having more than one reel allows for more convenient transportation and keeps you in operation if one of the reels requires service

MANEUVERABLE FRAME

The lightweight, ergonomic frame design makes the system more portable and easier to maneuver around cramped job sites

SCREEN MOUNTING OPTIONS

The control unit can be rotated and repositioned letting the installer set it in their ideal viewing position

AUTOMATED PULLBACK

The onboard computer controls pullback speed based on job parameters to fully cure the liner ensuring a quality result on every installation

INTEGRATED CAMERA

Easily monitor the progress and quality of the installation with the camera integrated into the LED light head

MORE THAN

NEW TOUCH SCREEN INTERFACE

The redesigned Bluelight system features an intuitive touch-screen interface that is easy to learn and operate. Simply input the job specs and the system will automatically set pull-back speed. On the screen, the installer can watch curing progress on a live feed from the LED light head’s integrated camera, and the boldly colored gauges make it simple to monitor the system’s performance throughout lining operations.

REQUEST A QUOTE

REQUEST A QUOTE

See other CIPP Products from HammerHead Trenchless:

QUICKLOCK INVERSION DRUMS

CIPP liner inversions drums featuring the patent-pending QuickLok door that seals in seconds with a single lever, and additional new user-friendly design enhancements.

'HEATWAVE' CURING SYSTEM

Re-designed hot-water curing system that integrates components into a single portalble unit resulting in increased performance and less equipment to haul around on the jobsite.

WT212-3D WET OUT TABLE

Newly designed automated wet-out table that features strategically placed rollers and rigid structure with cam-locking gap height adjustment system for greater wet out accuracy.